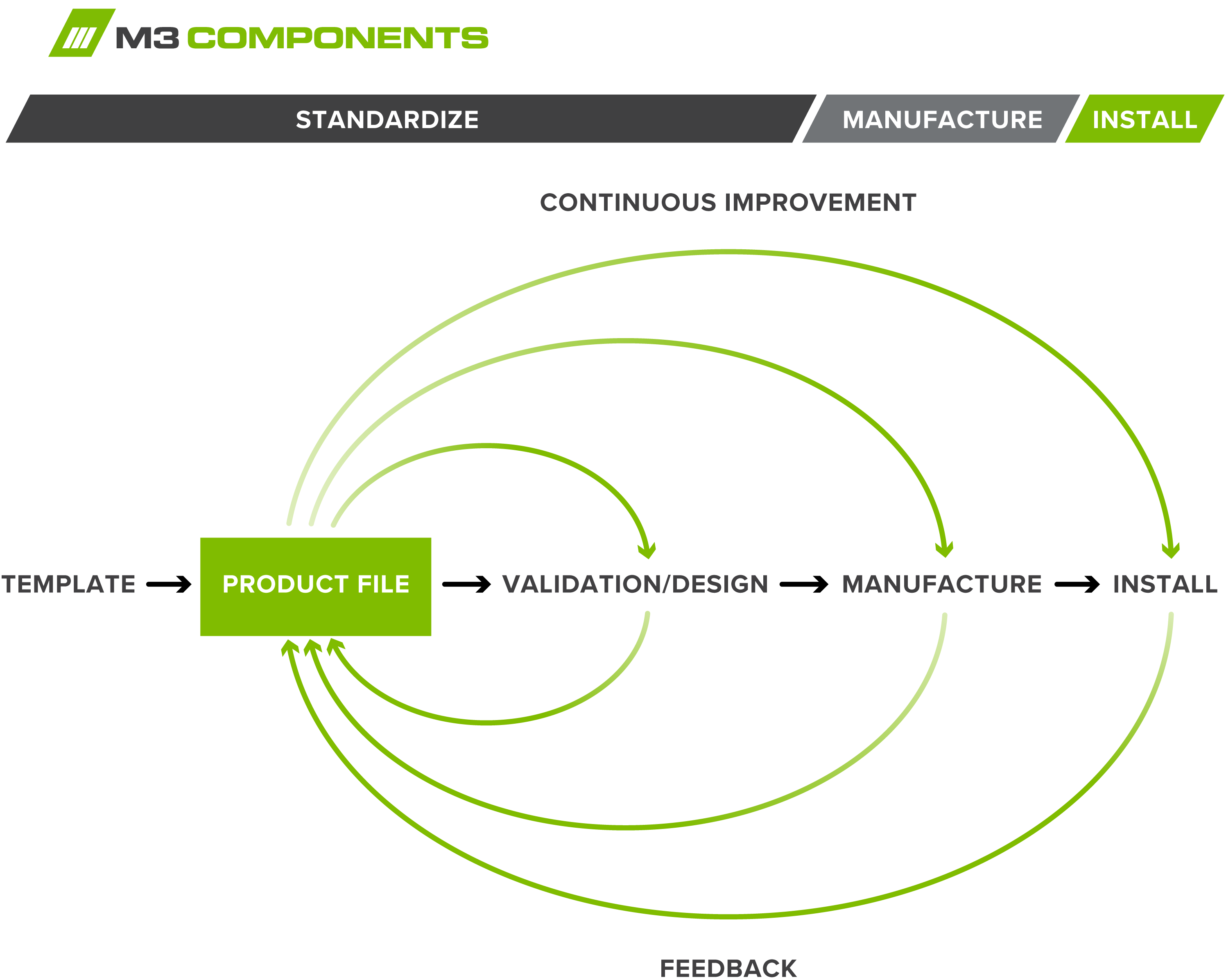

Process

Product Lifecycle

M3C’s product files are designed with continuous improvement in mind. Templates are used to develop the product file, and feedback loops are implemented at every phase in the process to ensure continuous improvement.

Manufacture

Building components are produced in a controlled, off-site factory setting and then transported to the site for installation. This allows for greater flexibility, higher quality, faster construction times, and increased sustainability.

FAQS

Industrialized construction is a methodology that views projects as products rather than stand-alone, one time projects. This includes high-volume, off-site construction, prefabrication, and manufacturing.

- Affordability & a more predictable outcome

- Shorter on-site durations

- Sustainability

- Safety

YES! Our products can be installed in both TI and new, ground-up facilities. Our team will work with you to determine what products will work best for your site conditions.

Panels are flat or vertically packed depending on features. Pods are wrapped with waterproof shrink-wrap that provides protection from the elements during loading, transportation, and staging. Upon delivery, certified installers unload the products using integrated lifting eyes and set in place using a roller system. Once set in place, the pods and/or panels are anchored and final connections are made.

On average, it takes 15 minutes to produce the light-gauge steel studs required for an M-Panel, and 120 minutes to complete an M-Pod from raw material. Once the framing is complete, electrical and plumbing assemblies are installed, finished, and applied trim-out is performed. A final inspection completes the process.

Yes. M-Pods without a built-up floor do not require a depressed slab.

Yes! We can manufacture pods for sites ranging from 1 to 10+ floors. Sky’s the limit!